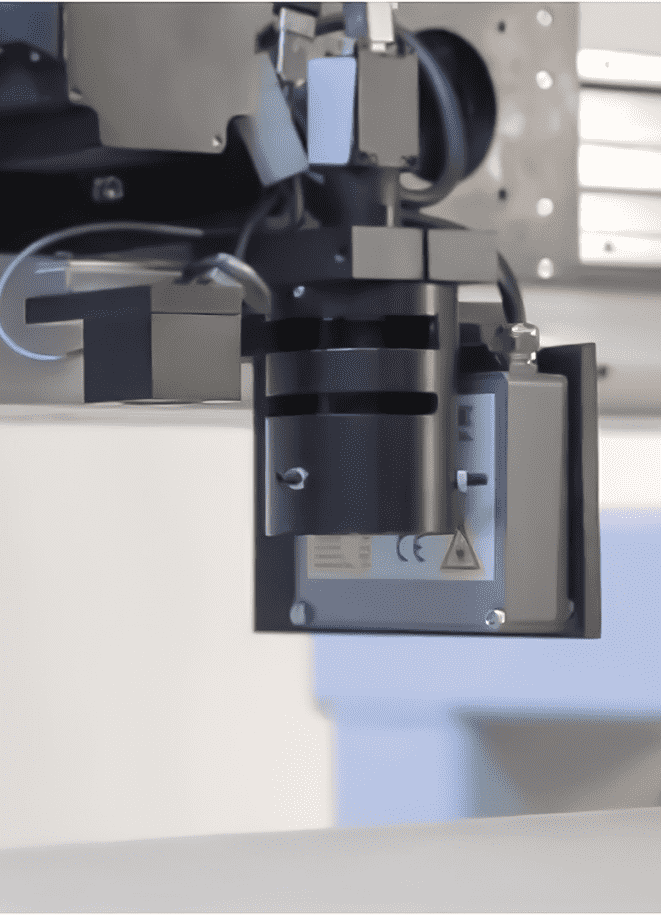

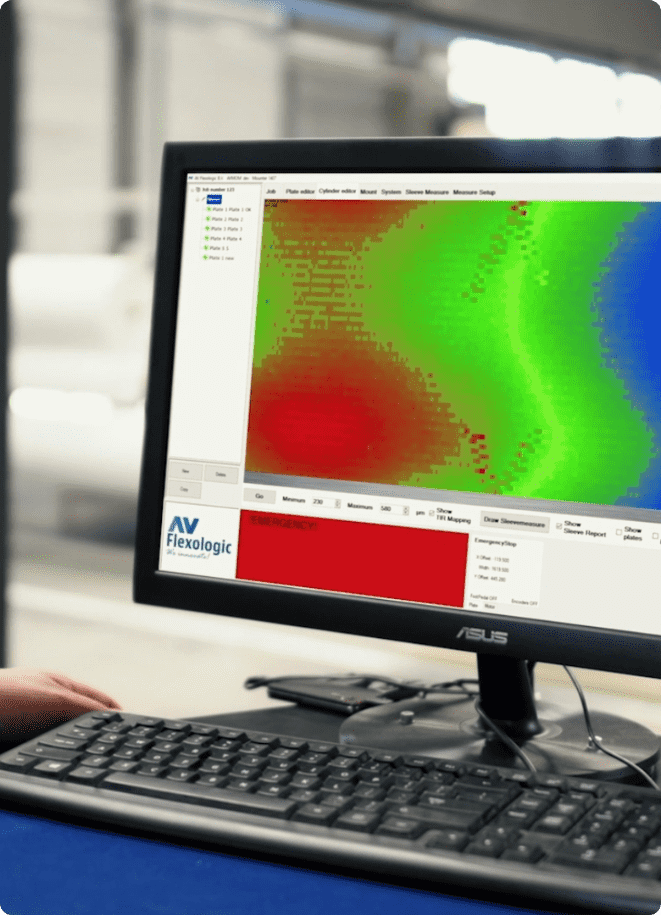

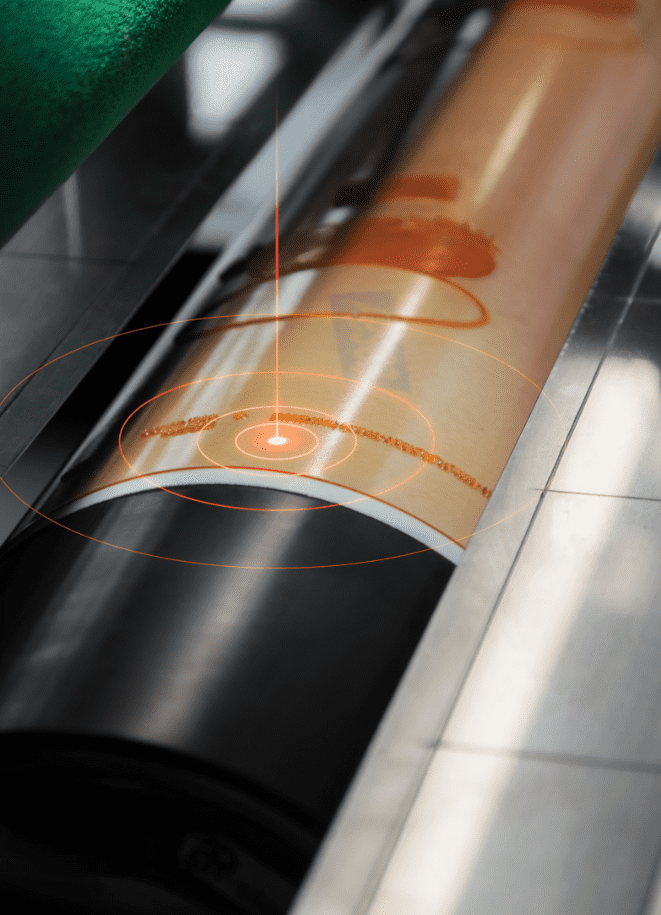

TIR Sleeve Measurement System

SLEEVE SCANNING AND REPORTING

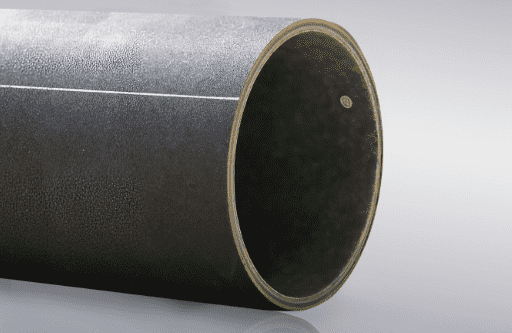

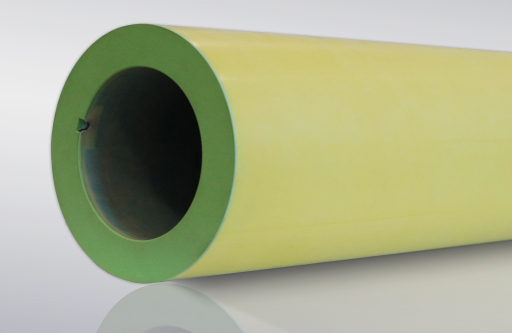

The TIR Sleeve Measurement System analyses the quality of the printing sleeve or cylinder by measuring the 3D landscape of the surface with an accuracy of 5 microns. The TIR system keeps track of the exact condition of each printing sleeve in stock, so that they can be placed in the press with the right settings. Worn out or damaged sleeves are easily detected, which prevents press downtime due to bad quality sleeves.

- Prevent press downtime by avoiding using worn out sleeves in the press

- Highest sleeve measurements with a quick scan

- Easily identify damaged sleeves

- Stores the measurement report

Testimonial

"Kliše-Kop has been working with Tech Sleeves for four successful years. Despite our experience and considerable knowledge about sleeves, the collaboration with experts from Tech Sleeves has ensured the upmost support and given total confidence if any problems were ever likely to be encountered. That is why when our clients are buying Tech Sleeves they are not only buying a fantastic product but also buying experience and support for the future."

Coveris is a global leader in making and distributing packing solutions.

"The technical service from the team at Tech Sleeves is second to none in my opinion. They were onsite multiple times to check that we received the correct number of sleeves and were constantly in contact with production in Holland. They were also flexible to modify their production schedule to meet our demands as they changed. The sleeves are also of good quality and the reinforced pin notch makes lining up the sleeve on the mandrel very easy, both in mounting and on the press."

Garlock Specializes in flexible packaging with over 30 years of experience.

Garlock was set up in the year 1987 when they started as a supplier fo gift tissue for retailers globally. Since then they have evolved to support the demands of the worldwide flexible market. Creating an unblemished track record of quality and service, they cater to various customers from well-established companies to start-ups. Garlock has been doing business with us since the year 2016. Being a service-oriented company with high focus on quality and customer satisfaction, Tech Sleeves is their choice for sleeve supplier.

KBA - Flexotecnica specializes in making printing and converting machines for flexible and rigid packaging.

KBA - Flexotecnica is a part of the Koenig & Bauer group. Flexotecnica was a separate company that made flexo presses to print on papaer and plastic for packaging purposes. In the year 2013, Flexotecnica merged with the KBA group, a global leader for making sheetfed and web offset printing press. KBA - Flexotecnica makes machines mostly for medical packages, pouches and bags, industrial bags, food packaging, labels and barrier films for special products, detergent packages, containers for liquids like milk, cosmetics and also carton tray for food.

Constantia Flexibles is a manufacture of tailor-made packaging solutions

They supply to various multinationals and local companies in food, pet food, pharmaceuticals and beverage industries. They believe in leading technology, highly efficient production facilities, premium positioning and customer proximity. Constantia conforms to the 4 P's of Packaging: Preservation, Protection, Promotion and Presentation. They understand that packaging is one of the most crucial products that serve a purpose for a brand and that it exists in various shapes, colours, sizes and designs. Therefore, they focus a lot on high quality. For a high-quality outcome, they need to ensure that they also have high-quality materials, which is why we have been their most preferred choice of sleeve supplier. Constantia is a happy customer that has been doing business with us since the year 2017.

SUPPLIER OF PRINTED FLEXIBLE PACKAGING MATERIALS

Creating a beautiful print for your packaging is their strength. For this, they use the Flexo printing technique. In 2012, ESKO Artwork was the first broadband printing company in the Netherlands certified as an HD flexographic printing company. In their print shop, they produce with the most modern printing machines from Comexi, which can print up to ten colours and are suitable for printing both very large and very small runs. They not only provide the desired package of a magnificent impression, but they also ensure that the material with a very high speed of processing, cleanly processed into ready-made articles. And for those printings, they have tested our Tech Sleeves whose fit perfectly in their machines making them able to print at premium quality at high-speed printings.

Contact us

At Tech Sleeves, we care about our customers, which is why we have designed our network to help you anytime, anywhere.

H. Kamerlingh Onnesweg 2

2408AW Alphen a/d Rijn

The Netherlands

+31 17 25 03 611

[email protected]