Tech Sleeve Light

HIGH-PERFORMANCE LIGHTWEIGHT FLEXO PRINTING SLEEVE

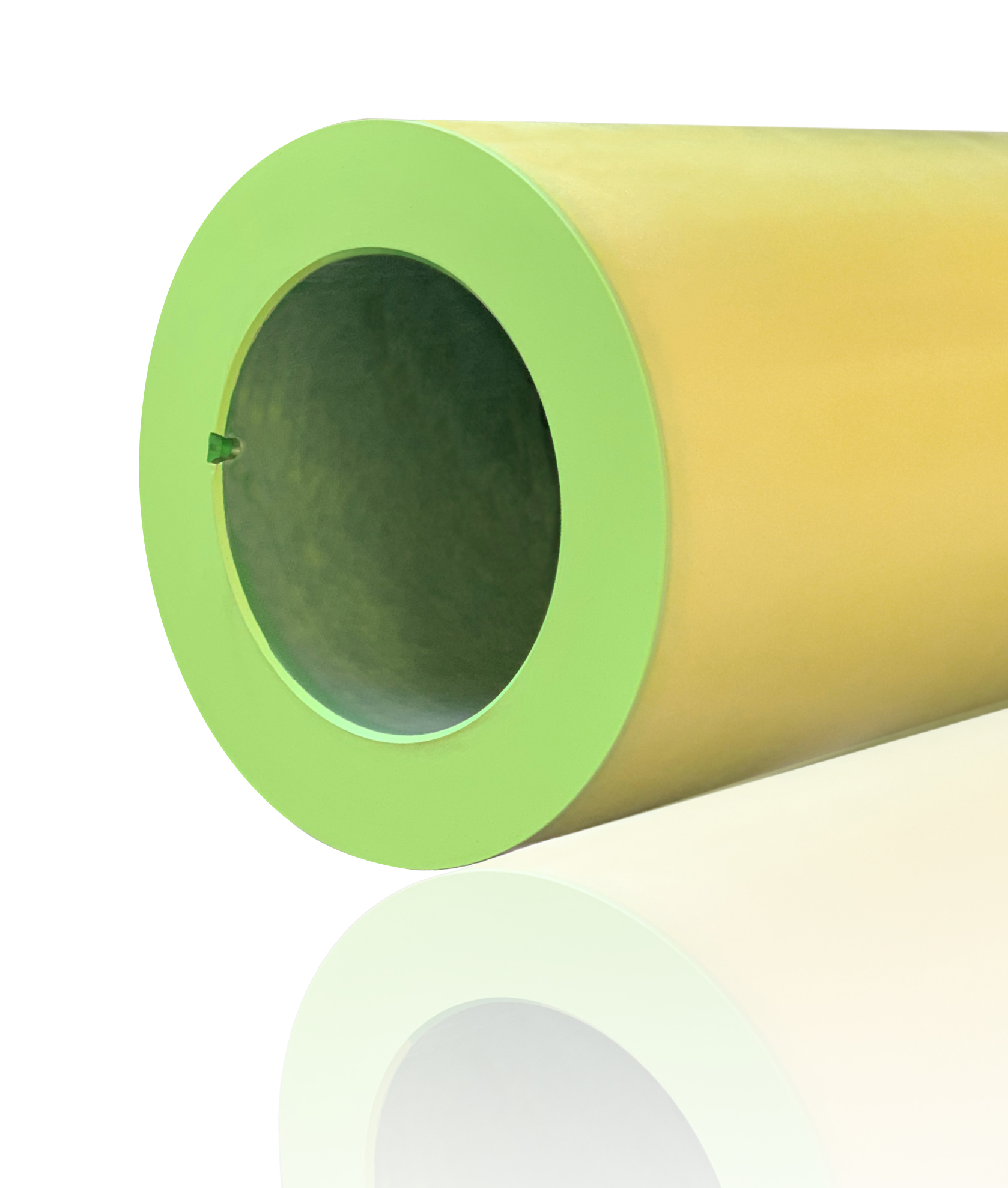

Tech Sleeve Light is a high-durable printing sleeve renowned for its exceptional lightness and stiffness. Our advanced mounting layers reduce vibrations, minimize press bounce, and enhance productivity and print quality, even at high speeds. Designed to meet diverse needs, the Tech Sleeve Light offers ease of operation and superior performance.

- Vinyl ester resin outer layer

- Advanced lightweight technology

- Bounce & vibration mitigation

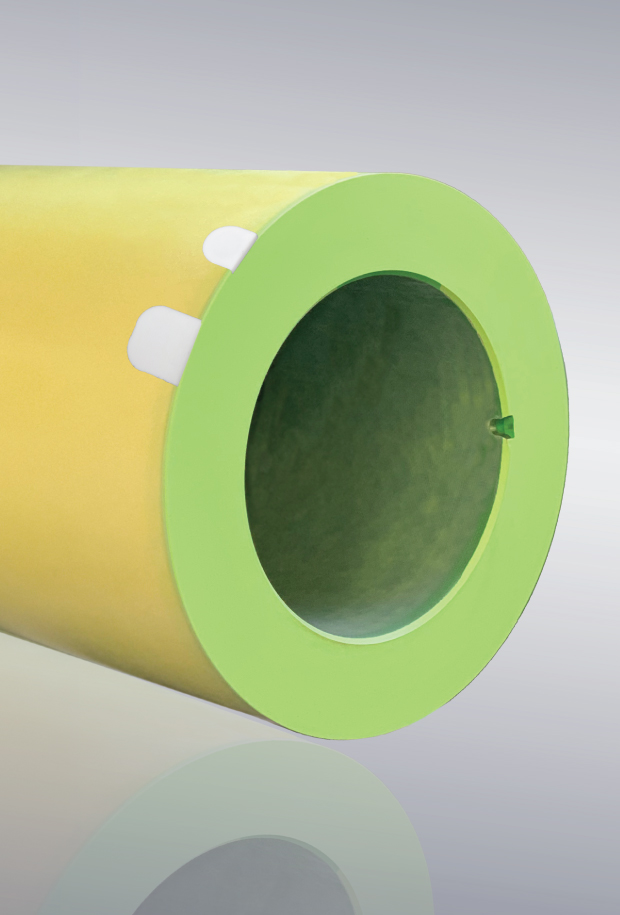

- Optional rubber ends and metal-reinforced notches

Benefits of tech sleeve light

Up to 20% Lighter sleeve

Advanced lightweight foam technology reduces the weight of the sleeve for up to 10-20% comparing to market average. (Example dimensions - Repeat: 1370cm/54 inches; Width: 1670cm/66 inches; Wall thickness: 20mm/0.8 inch; Weight: 19 kg/41 lbs)

Advantages

- Easy handling

- Less risks and injuries

Optimized Vibration Control

The foam layer acts as a dampener while the reinforced glass fiber layer disperses vibrations, resulting in reliable printing quality. This enhances precision and reduces maintenance needs, ensuring optimal performance and efficiency.

Advantages

- Stable and consistent

- Enhanced precision

Outstanding durability

The vinyl ester resin outer layer guarantees an 80 Shore D hardness, significantly exceeding the market standard. Optional rubber ends and metal-reinforced notches provide extra protection against edge decay and registration notch wear. These features guard against chemical and ink leakage, preventing sleeve swelling.

Advantages

- High pressure resistant

- Less turnover rate

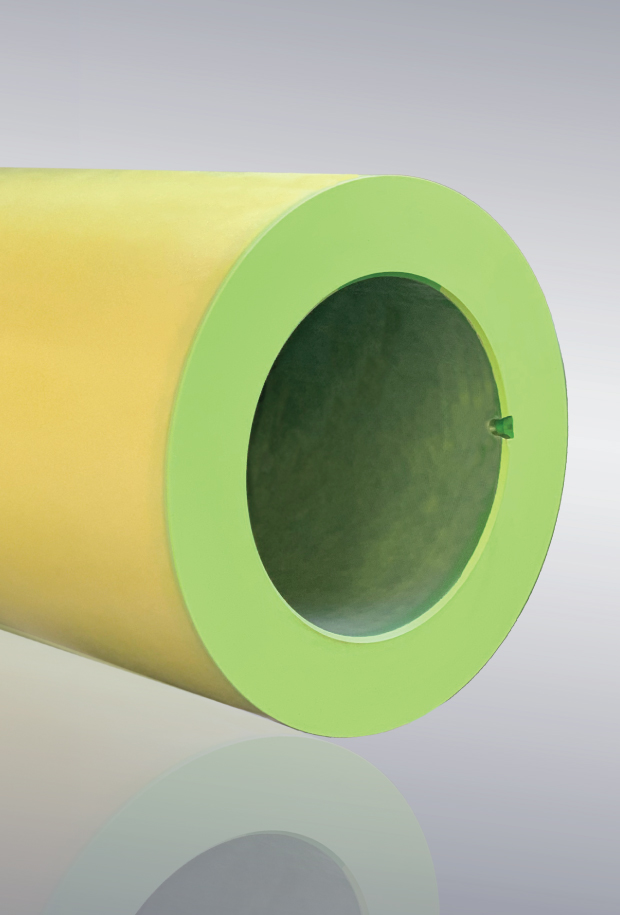

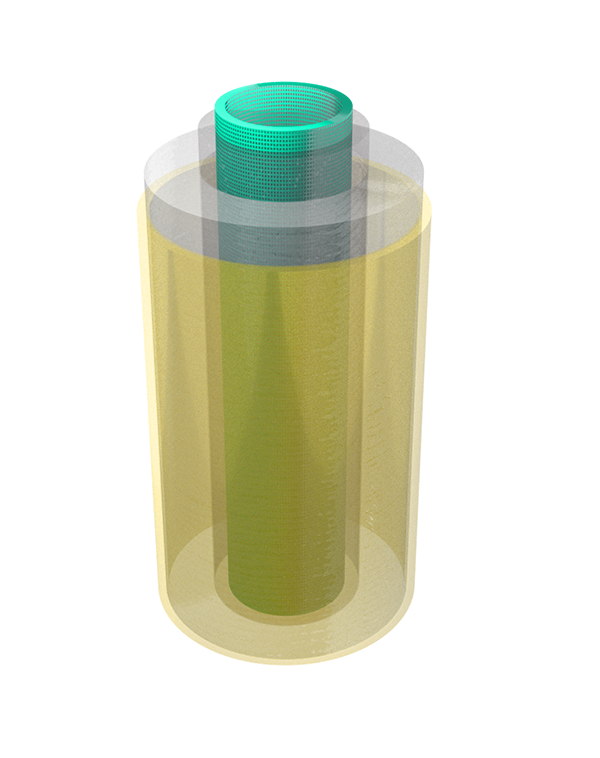

Sleeve Materials

Sleeve Materials

1

Base Layer

A flexible and expandable inner layer primarily consisting of glass fiber.

2

Compressible layer

Compressible foam rebound resilient layer.

3

Tech core light layer

Lightweight core material designed to limit bounce and maximize durability.

4

Hardened outer layer

Exceptionally hard and stiff outer layer (82 ShD) with UV cured Vinyl Ester resin.

Sleeve Versions

Testimonials

Rotolificio Bergamasco ERREBI

"What convinced us the most was the very competitive price. Our experience with Tech Sleeves has been positive from the very beginning. It can be immediately noticed that the sleeves, besides having excellent material, have a perfect adherence with the tape. Even during the detaping phase, they leave no residue. Once mounted on the press, we noticed that the registration was perfect, which is exactly what we were looking for." - Daniele Zambelli, ERREBI Print Quality Manager

Contact us

At Tech Sleeves, we care about our customers, which is why we have designed our network to help you anytime, anywhere.

H. Kamerlingh Onnesweg 2

2408AW Alphen a/d Rijn

The Netherlands

+31 17 25 03 611

[email protected]