Flexographic printing sleeves

What are flexographic printing sleeves?

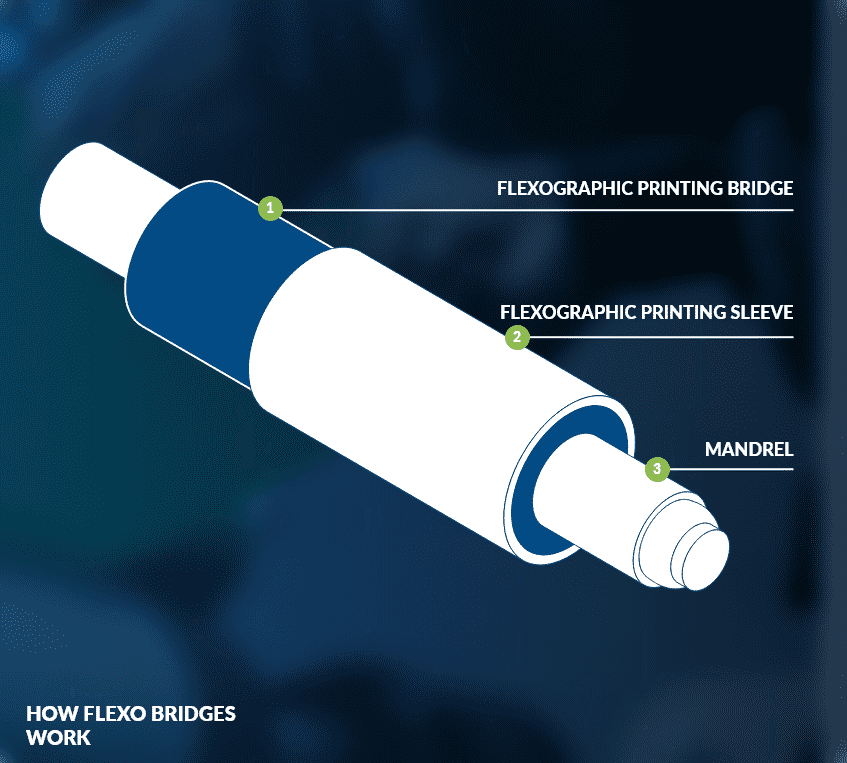

Flexographic printing sleeves are used to mount printing plates on it. Printing plates are mounted on the flexo plate sleeves, which are floated onto the air mandrel by using compressed air. Initially, flexographic printing plates were mounted on the cylinders directly. But since plates were not easily interchangeable and using multiple cylinders for several jobs lead to high costs and storage problems, flexo printing sleeves were developed. The main advantage of the flexo printing sleeves is that they can be easily floated on and off the air mandrels. The flexographic printing sleeves are also known as “Plate carriers”, “Plate sleeves” or “Press sleeves”.

Download brochureDiscover the best flexo sleeves in the market

Tech Sleeve Light

Top-of-the-range hard printing sleeve with Lightweight technology and improved durability and strength.

View product

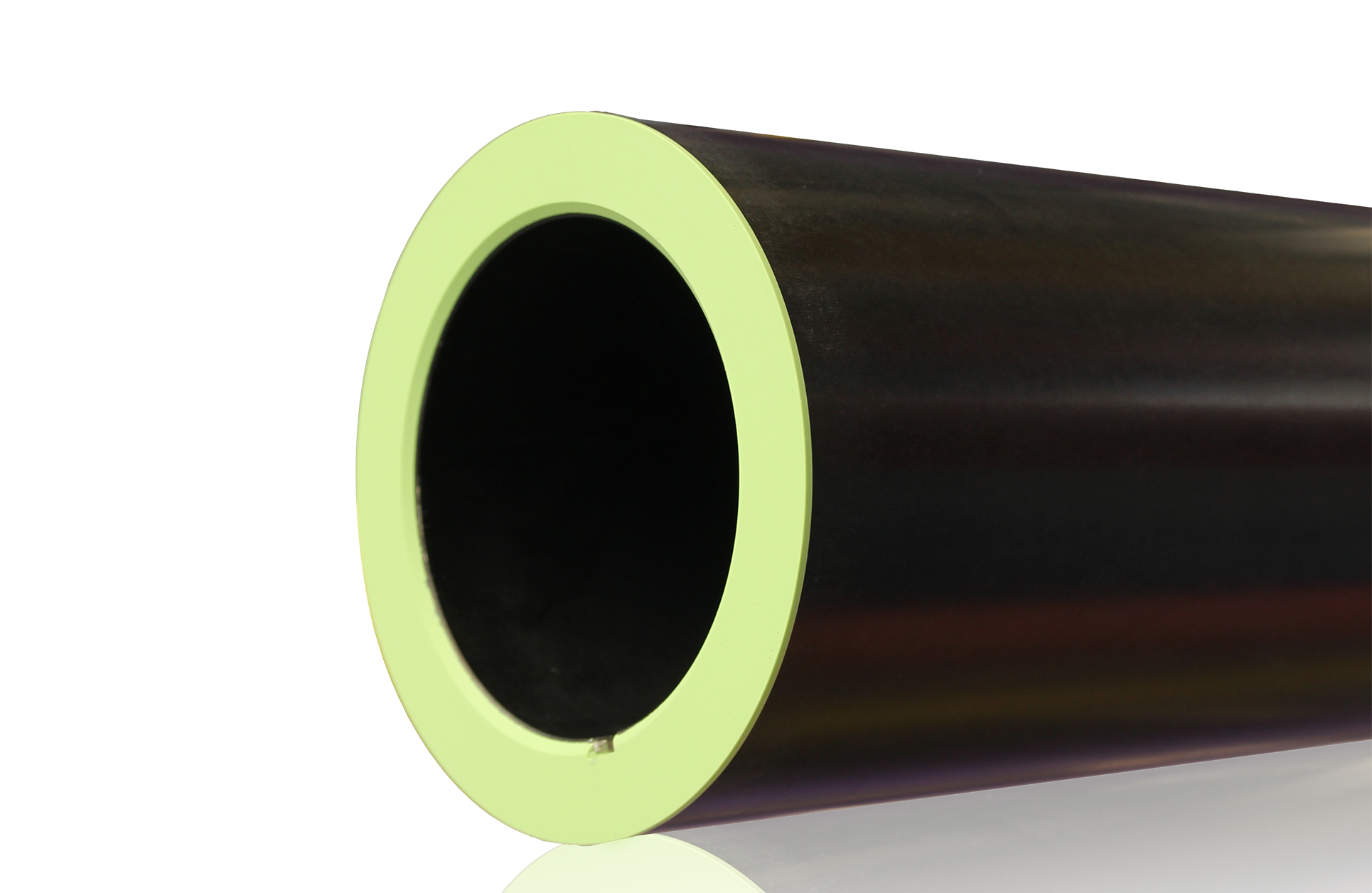

Conductive Sleeve

Conductive printing sleeve with advanced static elimination technology, delivering enhanced safety, consistency, and eco-friendly performance.

View productWhy is tech sleeve different?

Tech Sleeves is a flexo sleeve manufacturer. At Tech sleeves®, we offer plate sleeves and bridges (adapters) for the global flexographic printing industry. We believe that we can increase the printing quality and overall efficiency through a combination of experience and innovation.

Features and benefits of a Tech Sleeve

The high-quality raw materials such as the composite combination of volumized fiberglass infused with vinyl-ester epoxy resin, provides flexural strength and form stability to the Tech Sleeves, reducing the bouncing caused by deflection during printing.

Durable options such as rubber sealed edges

Built with the strongest materials

Stiffer sleeve in the flexo market

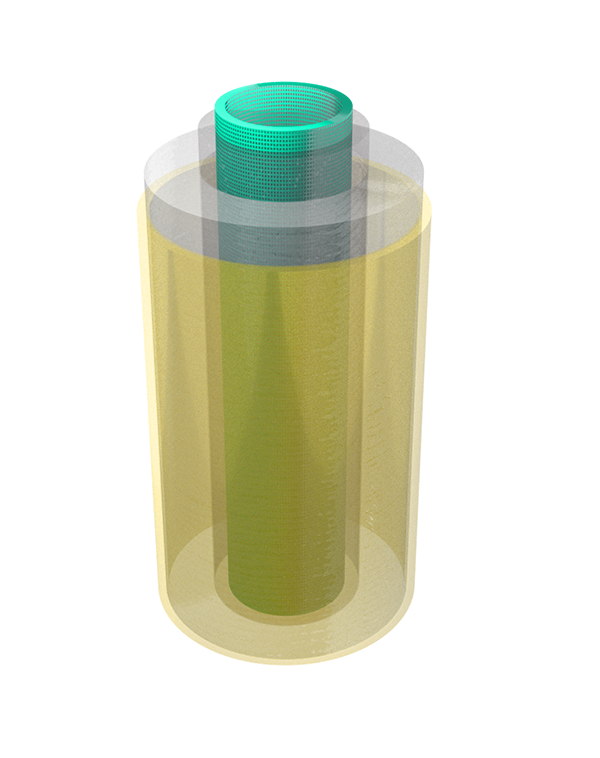

Sleeve Materials

Sleeve Materials

1

Base layer

The base layer features an expandable and an extremely durable base layer (1mm). Resistant to moisture, UV lights and chemicals.

2

Compressible Layer

The foam layer offers high rebound resilience and 50% compressibility without bulging. Because of this, it enables the sleeve to expand and have a perfect fit. Furthermore, the foam layer will not deform and has good abrasion resistance from ageing and weathering.

3

Tech Core Material Layer

Lightweight core material designed to limit bounce and maximize performance. Infused with Vinyl Ester Resin to offer dimensional stability.

4

Outer Surface Layer

The UV cured Vinyl Ester Resin improves toughness and has excellent chemical and corrosion resistance.