SUPPORTING EQUIPMENT

At Tech Sleeves, we are dedicated to serving the global scope of the flexographic printing industry with Bridges and Plate Sleeves. You can bank on us for: quality, innovation and reliable service.

DOWNLOAD BROCHURESUPPORTING EQUIPMENT

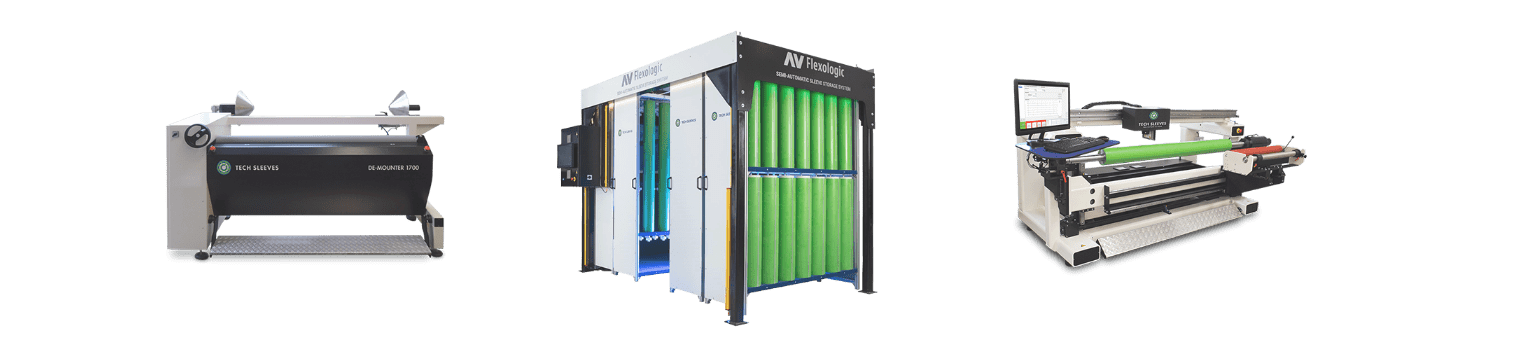

Sleeve Storage System

Our customized Sleeve storage system has been co-developed with AV Flexologic for workspace optimization in the prepress department while providing optimal protection for your sleeves.

View product

TIR Measurement System

The TIR Measurement System is designed to detect sleeve surface imperfections to ensure no mistakes occur during your printing process.

View productA brief history on flexo

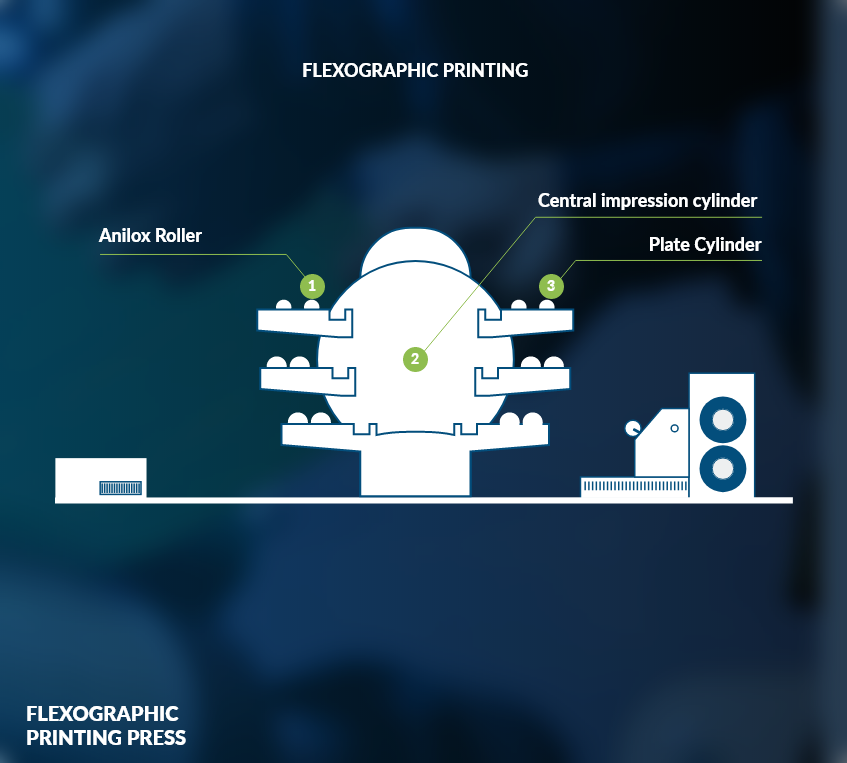

Flexography started as a rubber stamp printing method. In 1980, the first patented press using flexographic printing was built in Liverpool, England by Bibby, Baron and Sons. Flexography uses relief printing plates with raised images and fast-drying inks to print. It is a rotary in-line printing method that can use variable repeat lengths and enables printing with a broad range of inks and substrates.

Why flexo is so important

With the advancement in technology, flexographic presses have become the fastest-growing printing process in the world. It is challenging to imagine a day without crossing a flexographic product. Around you, you will find many products, be it grocery or office-supplies, which are packaged with flexographic printing. Business forms, flexible packaging for food and drinking products, labels, envelopes, wallpaper, gift wrapping paper, newspapers, textiles, labels, folding carton, foil are just some of the examples of flexographic printing products.

We offer efficient storage systems for flexo sleeves

Machines to monitor and maintain your sleeves

Efficient tools that make your job easier.