FLEXOGRAPHIC PRINTING BRIDGES

What are flexographic bridge sleeves?

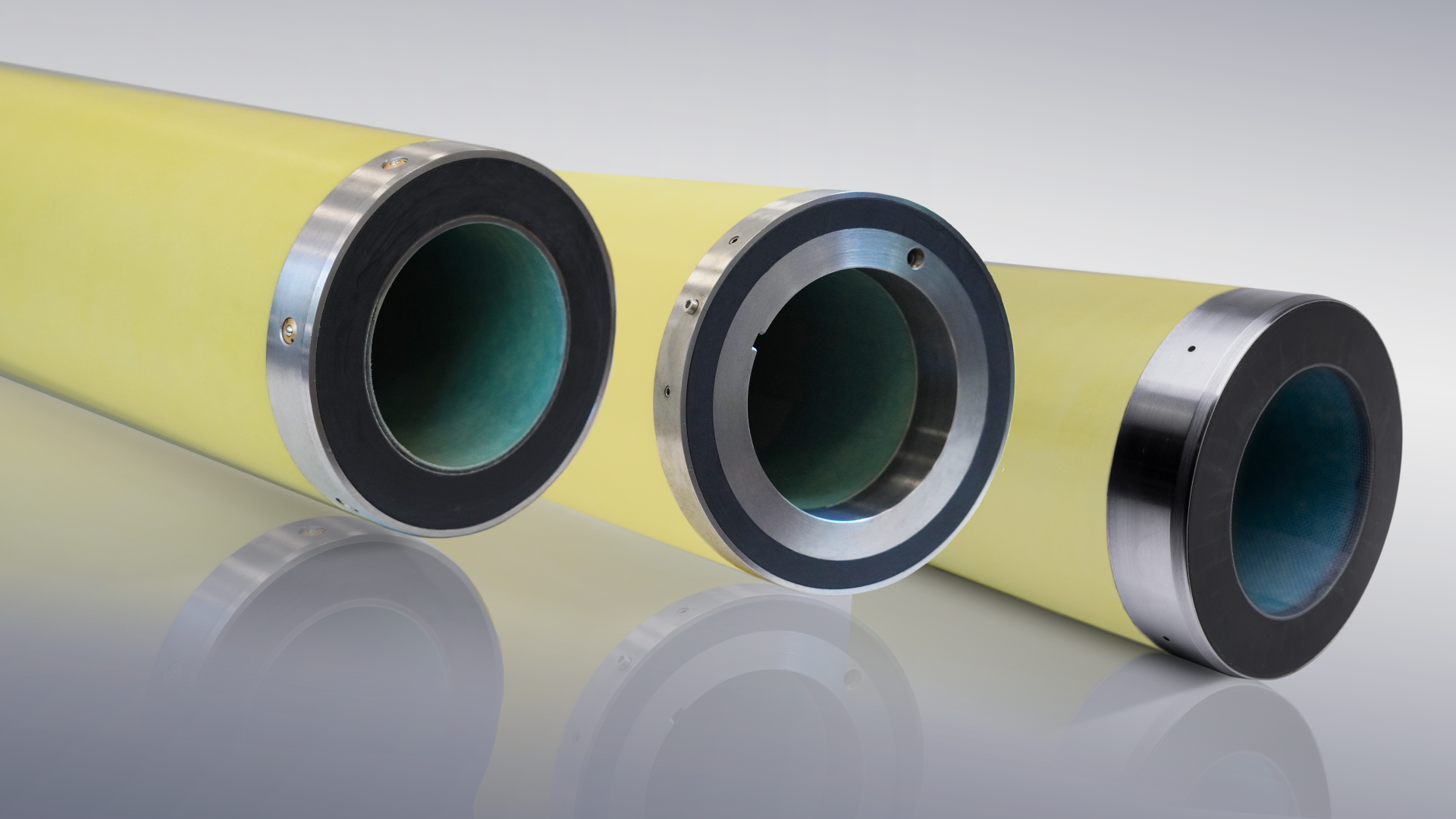

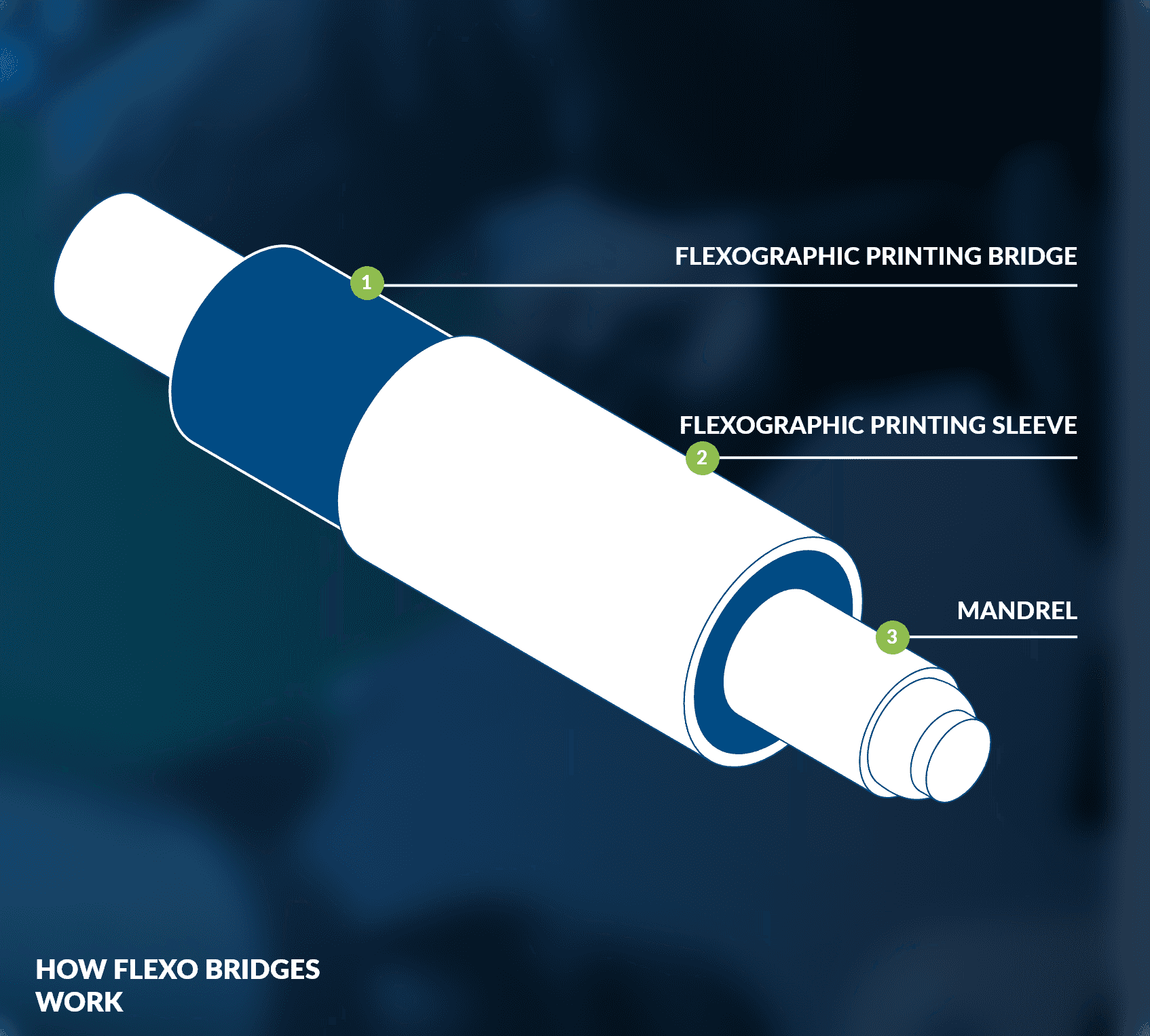

Flexographic bridge sleeves, also typically known as flexographic adapters or flexographic bridges are pneumatic or hydraulic adapters used in the flexographic printing industry to ‘bridge’ the gap between a printing press mandrel and the inner diameter of the printing sleeve. They are designed to increase the size of the mandrel in the press and are especially used when the outer diameter for the printing is big. Bridge sleeves are also known as adapter sleeves or format adapter sleeves, mounting adapters, carriers, bridging sleeves or flexographic bridge mandrels.

DOWNLOAD BROCHUREWhat different types of printing Bridges do we offer?

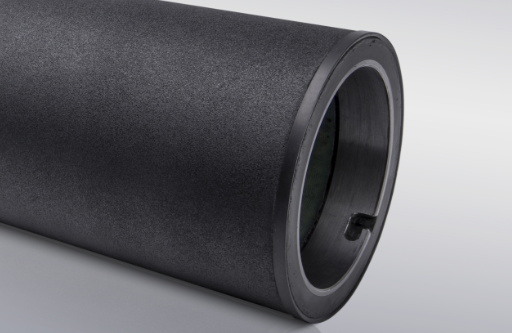

Compressible Bridge

Compressible Bridge designed for In The Round sleeves. These are specialised sleeves that are used to achieve seamless prints. The adapter can be configured with different hardnesses to ensure great printing results.

View product

Tech Bridge

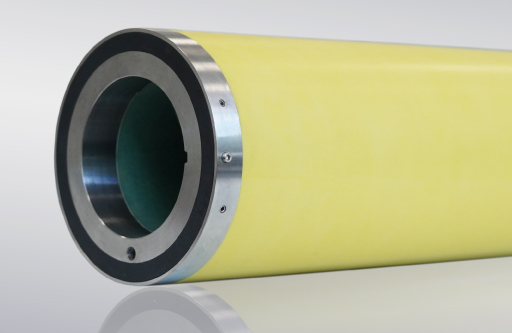

Tech Bridge is our most advanced bridge/adapter in the market. It is made using high-quality materials such as Dyneema for the inner layer and epoxy resin-infused fibreglass.

View productWhy is Tech Sleeve different?

Tech Sleeves is a flexo sleeve manufacturer. At Tech sleeves®, we offer plate sleeves and bridges (adapters) for the global flexographic printing industry. We believe that we can increase the printing quality and overall efficiency through a combination of experience and innovation.

Features and Benefits of a Tech Bridge

The use of high-quality raw materials such as the combined arrangement of vinyl-ester epoxy resin with Tech Core lightweight material, provide high flexural strength and form stability to Tech Bridges, reducing the bouncing while at the same time ensuring a better resistance.

Outer metal ring on both ends

Mount different sleeve widths with miller valves

Choose between Air-Through or Separate-Air

Materials

Materials

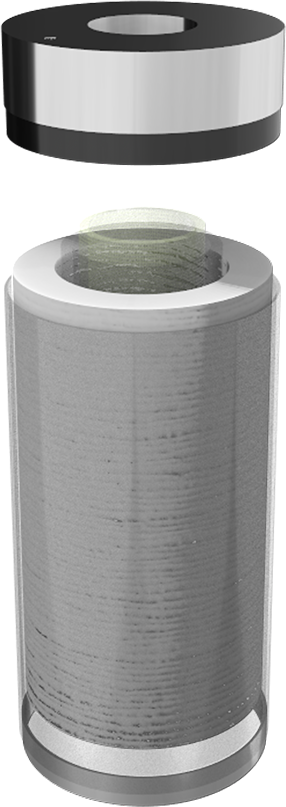

1

Base Layer

Stretchable without cracking inner layer with minimum weight and great abrasion resistance.

2

Compressible Layer

This is a compressible foam layer that offers high rebound resilience and enables the sleeve to expand and have a perfect fit.

3

Tech Core Layer

Contains Sphere Core SBC which is a stitch-bonded material based on fibreglass. It offers great pressure resistance, water resistance and stability.

4

Outer surface layer

Contains Vinyl-Ester resin reinforced by a sandwich construction of fibreglass material which has great temperature and chemical resistance. See compressible bridge for ITR adapters.