Eight Tips to improve the life span of your sleeves

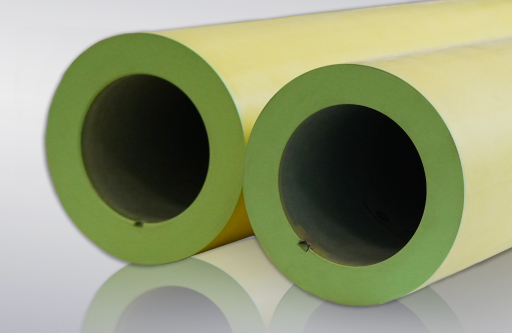

Although highly durable, sleeves still require some procedures and steps to extract their best performance during printing. These steps below will help highlight how to store and take your sleeves so you can benefit from their benefits for a long period of time.

The tips below illustrate how to use and care for your sleeves in order to get the best performance.

1. Wait for 24 hours Before Use

When you purchase sleeves, considering that each operating location is different, both in moisture content in the air and temperature, sleeves may react differently if they are used immediately. To mitigate this or to prevent possible print quality issues, you need to let sleeves rest for at least 24 hrs before use.

2. How to Store Sleeves

The way you store sleeves is critical to maximising their lifespan. One major issue is if stored on top of each other horizontally, this will create deformation issues as the weight of other sleeves presses down on the ones below The best way is to store sleeves vertically. Additionally, this can also cause surface damage on the sleeves. The best method is to use a horizontal sleeve system like the one we provide or your own system that elevates any forces that can cause damage.

3. Wait 20 Seconds When Mounting

CDA forms a cushion to mount and demount the sleeves smoothly. Waiting approx. 20 seconds to allow this air to escape ensures proper mounting.

4. Dry Before Use

Allow the sleeves to dry as using a wet sleeve may cause the tape to not stick properly, resulting in substandard prints. This also requires the sleeves to be stored in a moisture-free location.

5. Avoid Silicon Sprays

Although great for many use cases, silicon spray can cause issues when used with on sleeves and should be avoided in all cases. The main issue is it will cause tape adhesion issues for the sleeves which can lead to slippage and printing issues.

6. Spread Force Evenly

Avoid exerting excessive pressure towards the edges of the plate or tape while demounting it due to it cause poor alignment and can lead to uneven plate mounting. Always spread the force evenly.

7. Cutting Knife Positioning

When positioning the cutting knife, ensure it is done at a slight angle on the tape and ensure the tape is aligned and with tension.

8. Clean Before Use

Clean the sleeve before use to remove the dust particles are removed because they can prevent proper adhesion of the tape. Learn how to best improve the life span of your sleeves with some hints and best practices.

Contact our team for any question about our premium sleeves!