How we build durable flexo sleeves.

Building a durable sleeve that lasts takes careful use of the right materials, the right construction method and bringing it all together. In this video we cover the in-depth process that we go through in building sleeves that ensure your printing process remains the highest quality it can be.

We build our sleeves using three main steps and layers.

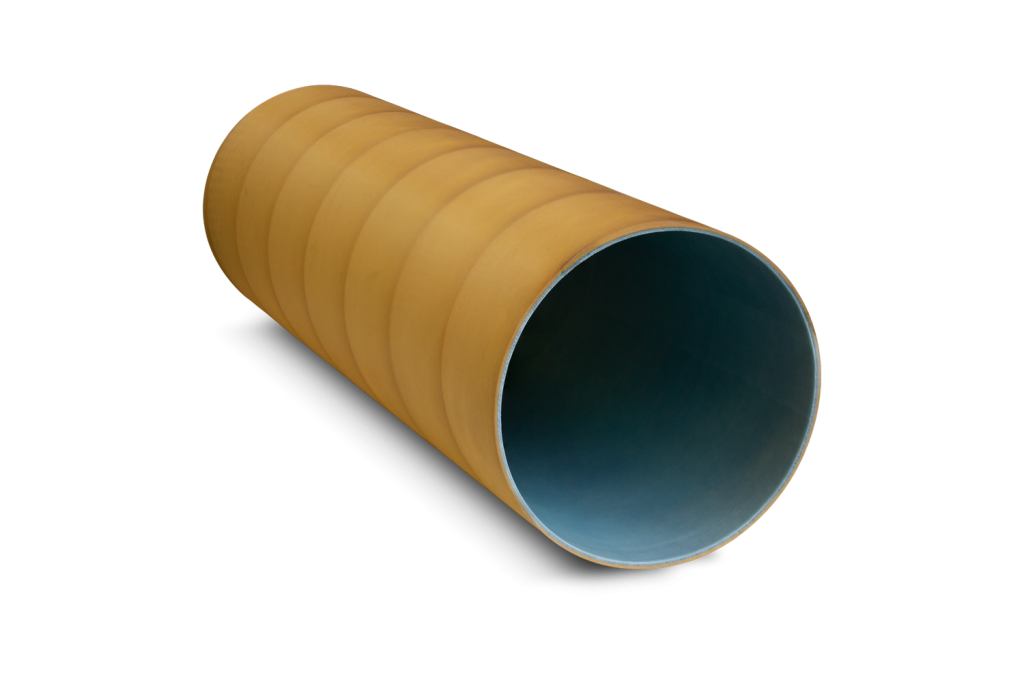

1. Compressible Foam Layer

The next layer is the compressible foam layer. This layer provides a number of benefits. The first is it allows for a tighter and more secure grip on the mandrel. This means reduced slippage in addition to the Dyneema layer. The second benefit of the compressible foam layer is rebound resilience which reduces printing mistakes.

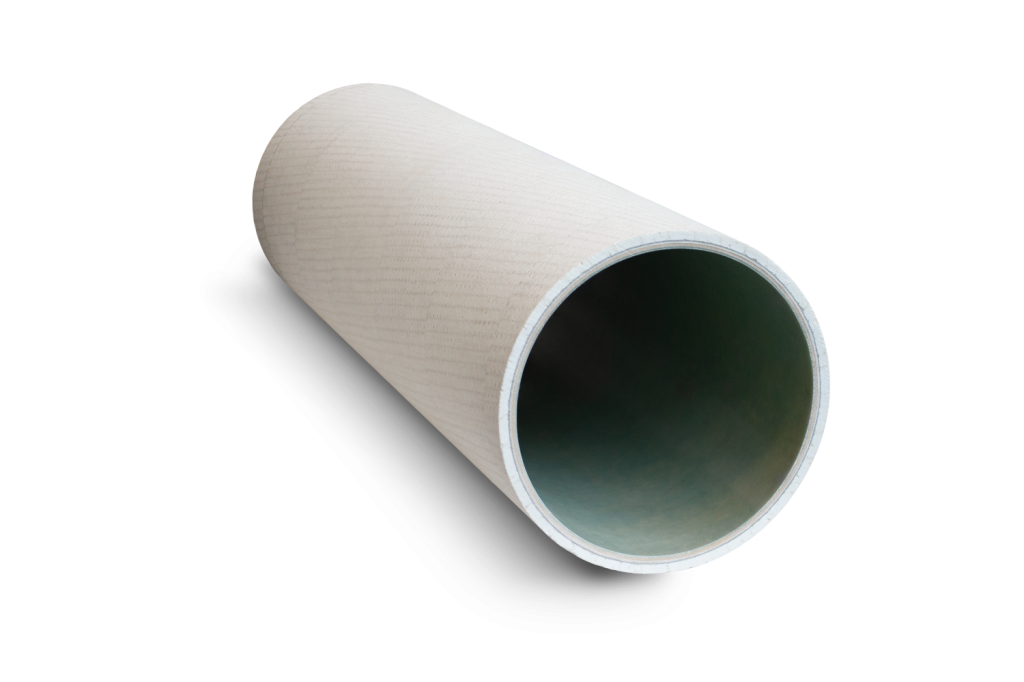

2. Tech Core Material Layer

The Tech Core Material layer is the backbone of our sleeves. It is made with a combination of Vinyle Ester Resin and Fiberglass. This makes the sleeve stiff and hard. Due to this, the sleeve is highly durable against various forces and prevents issues such as swelling.

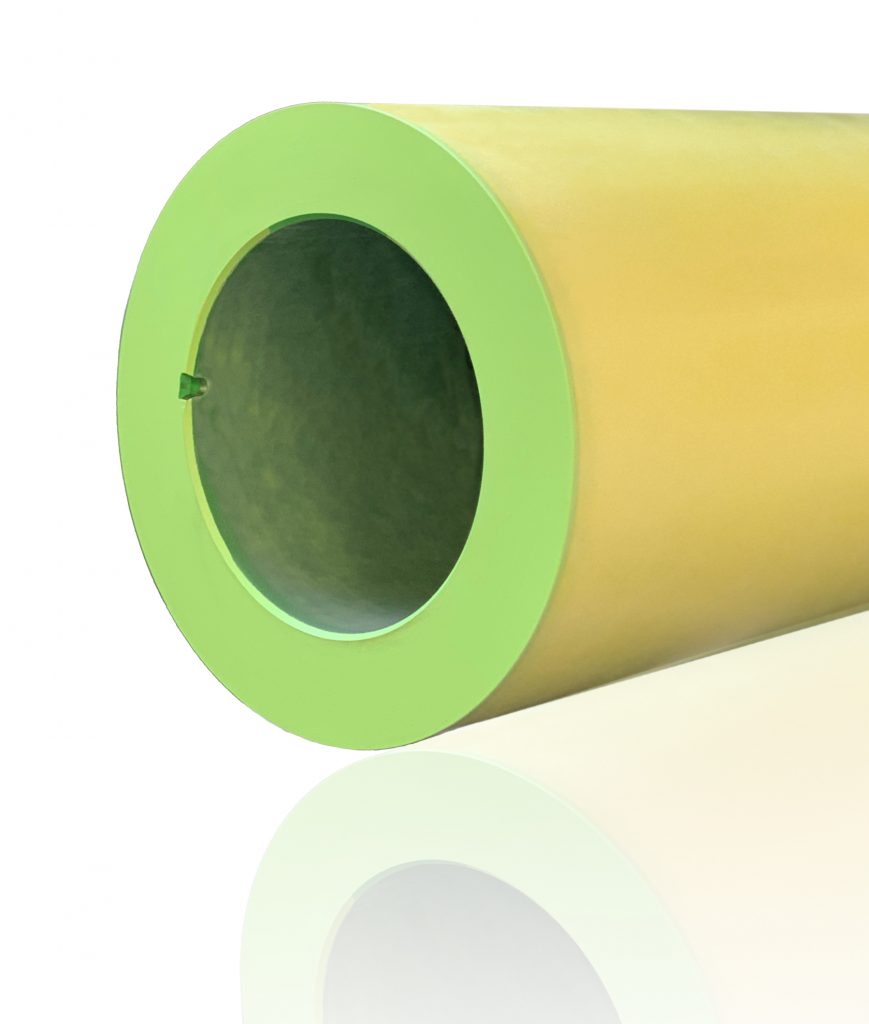

3. Outer Surface Layer

The outer surface layer is a chemical resistant layer ensures no moisture enters the sleeve with the added benefit of great adhesion with all popular tape brands.

Contact our team for any question about our premium sleeves!