Find the perfect sleeve for your needs

At Tech Sleeves, we know that one style doesn’t fit all when it comes to flexographic printing. That’s why we’ve designed a comprehensive portfolio of sleeves to meet a wide range of printing requirements. From standard printing needs to high-speed, complex jobs, our sleeves are built for performance, precision, and durability.

Our tight tolerances and sturdy notch ensure precise registration by stopping sleeve movement.

Achieve easy handling and great strength with our lightweight carbon and glass fiber blend.

Run confidently, knowing our sleeves resist chemicals and high temperatures.

Integrate our solutions into your workflow with a flexible and customizable product range.

Reduce setup errors and streamline job changes.

Maintain consistent quality at the highest speeds.

Optimize performance and improve your return on investment.

Access our worldwide network of flexo industry experts.

The gold standard in efficiency

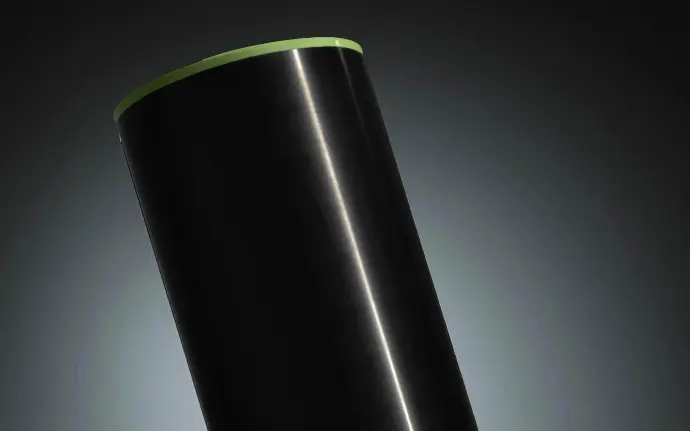

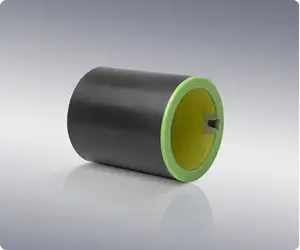

Tech Standard

This sleeve is the perfect balance of performance and cost-efficiency.

It offers:

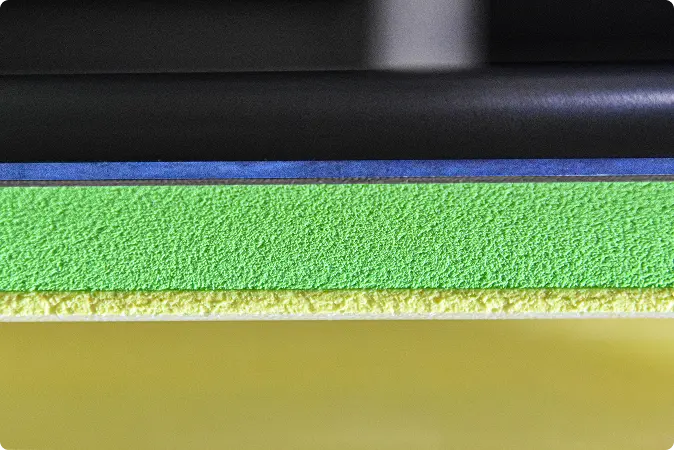

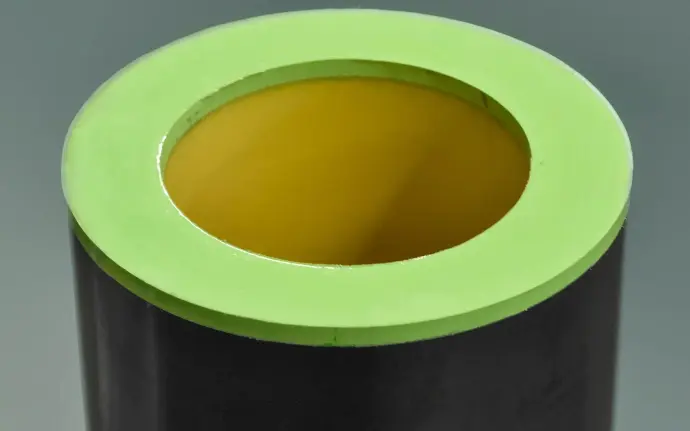

- A lightweight build-up formula for easy handling.

- Internal glass fiber layer for stability.

- 2 or 3 internal glass fiber layers for increased stability

- A 5mm Tech Guard outer layer for enhanced durability.

- Default composite notch

Ideal for all standard printing applications.

The most efficient printing sleeve to get the job done.

Designed for high-speed & complex jobs

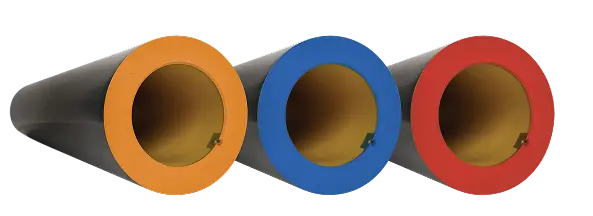

Tech Pro

Engineered for demanding printing environments.

It offers:

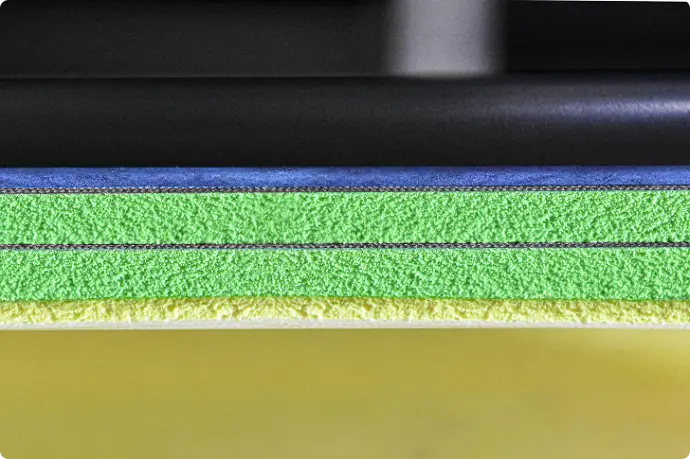

- Exceptional durability & stiffness for print performance -Conductive properties for enhanced safety

- Bounce mitigation for consistent quality at high speeds.

- 2 or 3 internal glass fiber layers for increased stability

- A 5mm Tech Guard outer layer for robust protection and enhanced durability.

- A composite notch

Ideal for high-speed printing, complex jobs and maximizing output on new presses

Tech Standard

Ideal for: All standard printing applications. The most efficient printing sleeve to get the job done.

- A lightweight build-up formula for easy handling.

- Internal glass fiber layer ensures stability.

- The perfect balance of performance and cost-efficiency.

Tech Pro

Ideal for: High-speed printing, complex jobs, and maximizing output on new presses.

- Exceptional durability and stiffness for print performance.

- Bounce mitigation for consistent quality at high speeds.

- Conductive properties for enhanced safety.

Sleeve Features

Looking for a custom option?

Get in touch with our team by clicking the button below.

Contact Us