H. Kamerlingh Onnesweg 2

2408 AW Alphen aan den Rijn

Netherlands

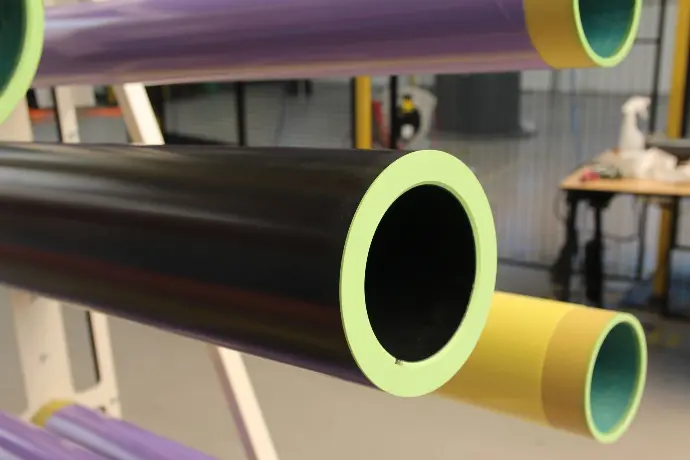

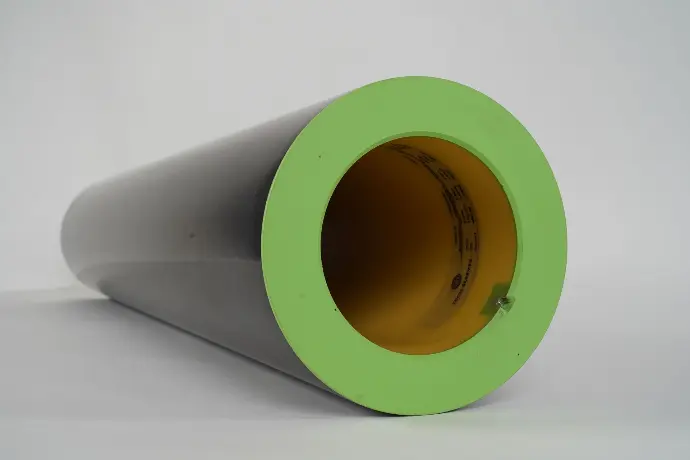

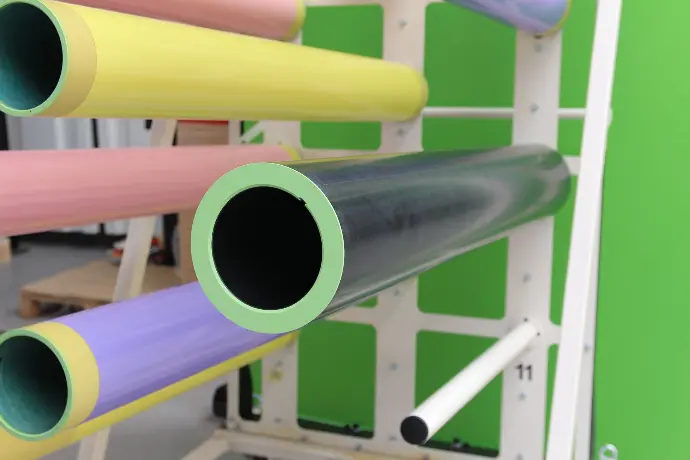

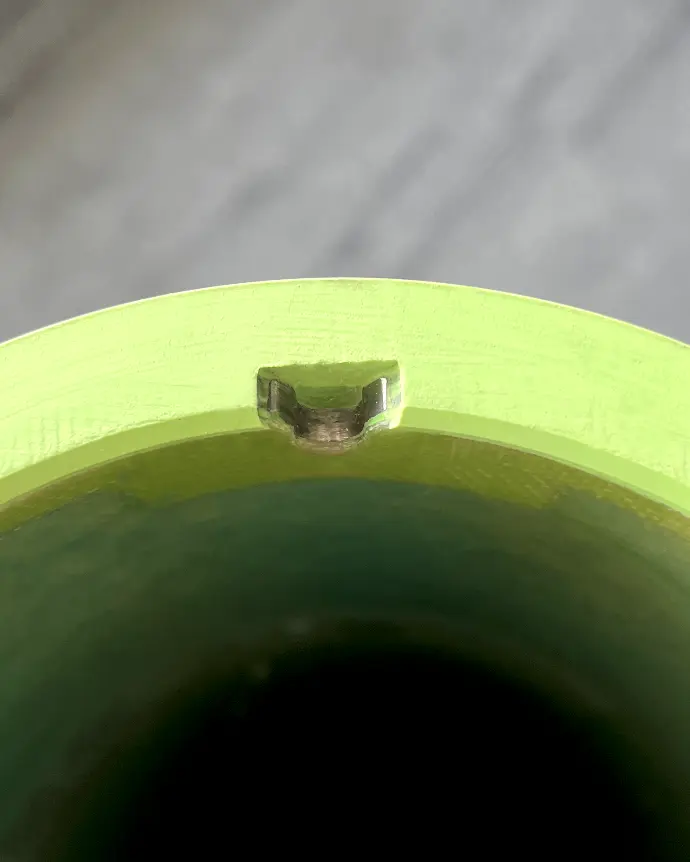

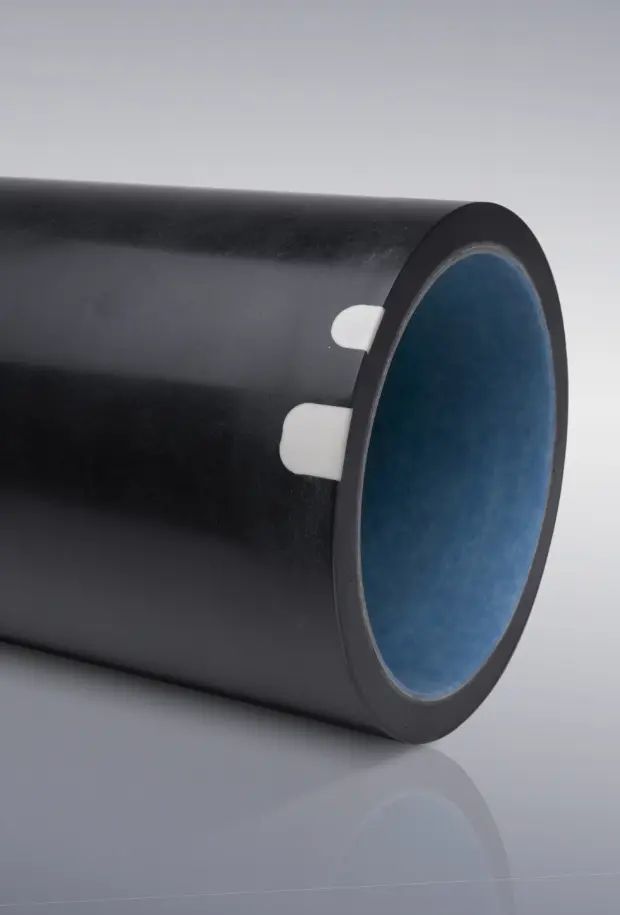

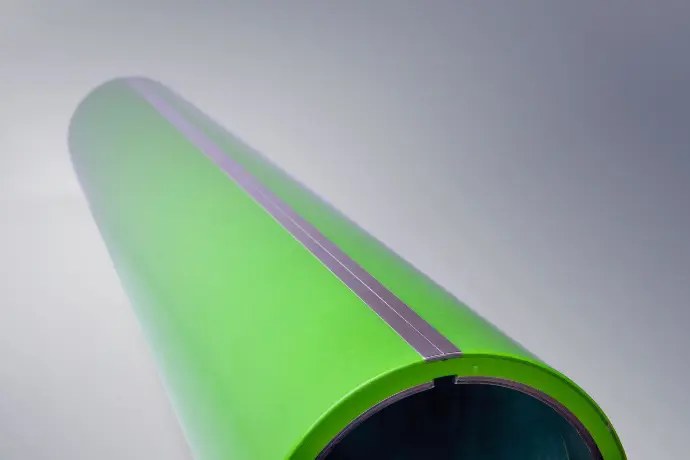

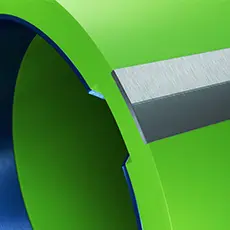

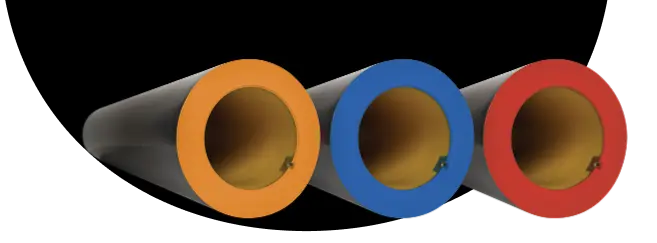

Sleeves Options

This block is filled dynamically. If you want to edit the contents you have to go to the backend.

Contact Our Team

Get in touch with us for any questions about our company or services.

We will do our best to get back to you promptly.

map_search

Address

phone_in_talk

Phone Number

alternate_email

Contact Information

Want To Learn More?

Reach out to explore our full product range of sleeves, adapters, and supporting equipment.

Contact Us