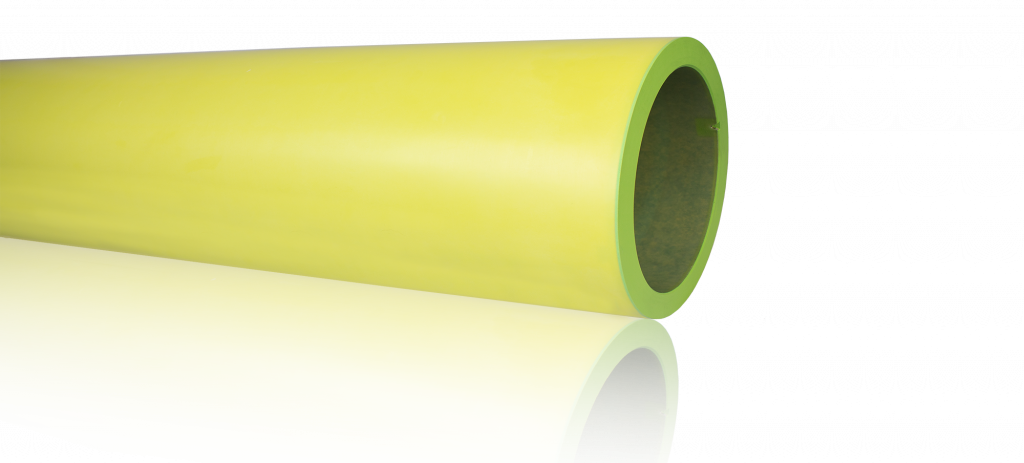

Constant high printing quality with compressible sleeves

Compressible sleeves have an outside cushion layer. By making use of compressible sleeves you create more standardization, more constant print quality and a reduction of your tape costs of 30%. This special outer layer is made out of cellular, water crossed-linked foamed polyurethane.

The properties of compressible sleeves

The soft, cushion layer can be offered in different kind of densities: 40, 50 and 60 Shore hardness.

Printing

The use of soft sleeves reduces bouncing. Also, soft sleeves create standardization in the printing process. Due to better tolerance, it is possible to have higher print speeds and pressure.

Quality

The tolerance of compressible sleeves with plate is 7.5% better than a regular sleeve with plate and cushion tape.

Savings

With this compressible layer, you use non-compressible thin tape which saves up to 30% costs. It is also possible to store sleeves with plates mounted on it, without reducing the compressibility!

Why use compressible plate sleeves?

Tech Sleeves has chosen for cellular, water-crossed linked foamed polyurethane because its a special material with great high-value properties such as:

High rebound resilience

- Up to 50% compressible without bulging.

- Resistant to permanent deformation.

- Good abrasion resistance.

- Resistance to ageing and weathering.

- Resistance to cleaning solvents used for polymer plates.

- Compressible sleeves help with the reduction of bouncing and can come in a selection of shore hardness.

Contact our team for any question about our premium sleeves!